The browser you are using is not supported. Please consider using a modern browser.

The Science of Perfect Prints: Understanding Mesh Count and Screen Tension

The Science of Perfect Prints: Understanding Mesh Count and Screen Tension

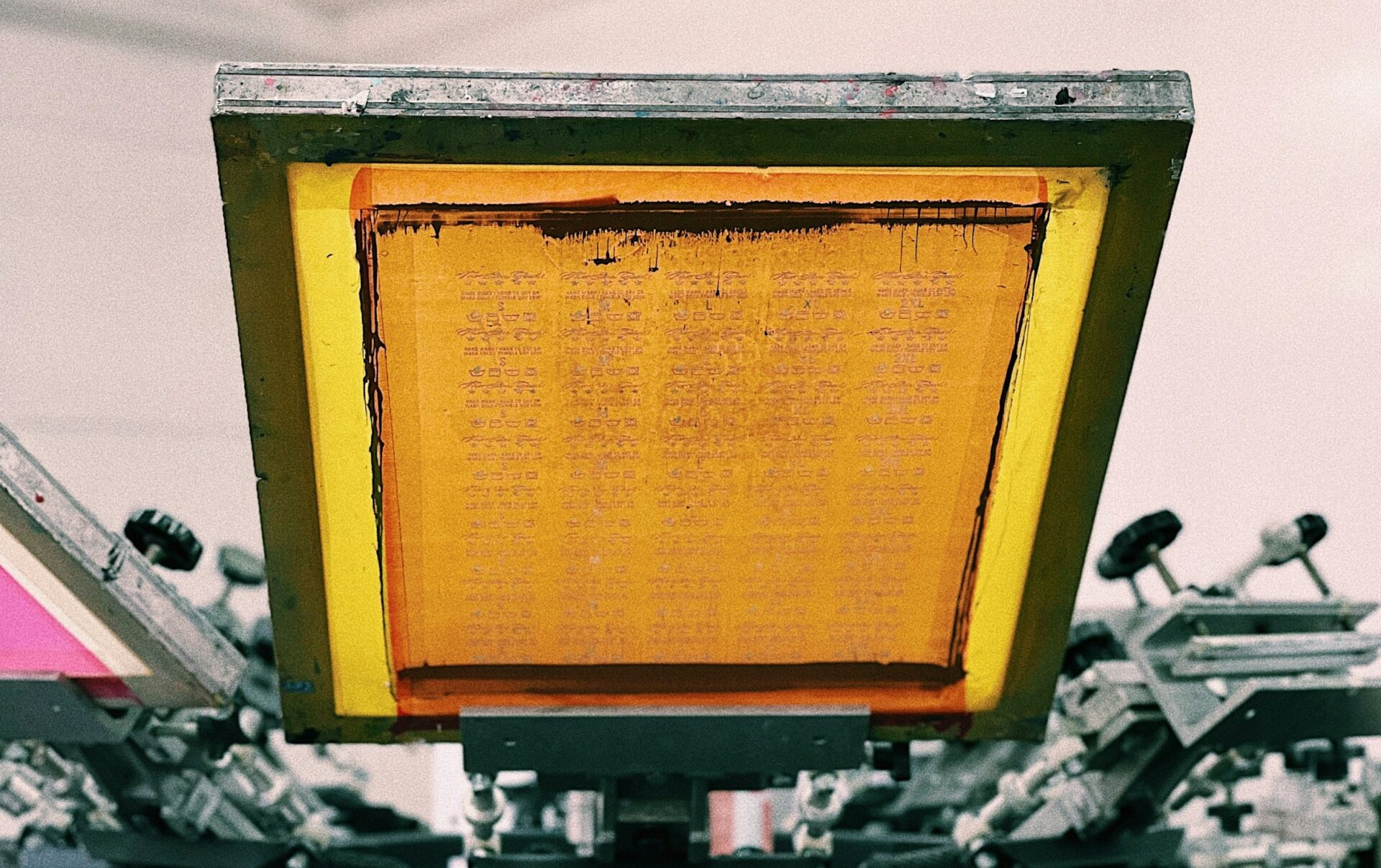

Screen printing is a versatile and intricate art form. Beyond design creativity, technical precision plays a pivotal role in producing high-quality prints. Among these technical factors, mesh count and screen tension are critical. These two elements determine the level of detail in your design, the vibrancy of colors, and the overall durability of your print. Let’s delve deeper into these essential concepts to help you perfect your craft.

What is Mesh Count?

Mesh count refers to the number of threads per inch (TPI) within the screen’s mesh. This number directly impacts how much ink passes through the screen and the level of detail your design will maintain. Higher meshes have more threads per inch, allowing less ink to pass through, which is perfect for fine details. Conversely, lower mesh counts let more ink flow, ideal for bold, simple designs.

Understanding Different Meshes

- Low (80–110):

- Suitable for bold and large designs, such as text or logos.

- Best for thick inks like metallic or puff inks, which need more ink to create texture.

- Commonly used for fabrics with a rough surface, such as burlap or canvas.

- Medium (156–230):

- The most versatile option for various projects.

- Perfect for printing on standard garments like T-shirts.

- Provides a balance of ink flow and design detail.

- High (305+):

- Ideal for intricate designs, fine lines, and halftones.

- Ensures precise ink application for clean edges.

- Best for materials like paper, plastics, or smooth surfaces.

What is Screen Tension?

Screen tension refers to the tautness of the mesh stretched across the frame. Proper tension ensures consistent ink transfer, clear details, and reduces the likelihood of print errors. Think of screen tension as the foundation of your print—without it, even the best designs can fail.

The Role of Screen Tension in Printing

- High Tension:

- Offers sharp, clean lines.

- Ensures smoother gradients and even ink distribution.

- Reduces the risk of screen movement during printing, maintaining registration accuracy for multi-color designs.

- Low Tension:

- Can result in smudged or blurred prints.

- Leads to uneven ink application, causing some areas to appear lighter or thicker.

- Increases wear and tear on your stencil due to unnecessary movement.

Tips for Managing Mesh Count and Tension

Achieving optimal results requires the right combination of mesh count and tension. Here are expert tips to help you refine your process:

- Match Mesh Count to the Design’s Needs:

- For bold and simple designs, use lower mesh counts to achieve adequate ink coverage.

- For detailed and intricate graphics, choose higher mesh counts for sharpness and clarity.

- Maintain Proper Screen Tension:

- Regularly check tension using a tension meter to prevent inconsistencies.

- Re-stretch screens or replace worn-out meshes to ensure longevity and reliability.

- Choose the Right Frame Material:

- Opt for aluminum frames, which resist warping and maintain even tension longer than wood frames.

- Test Before Printing:

- Conduct test prints to check for uniform ink distribution and detail retention.

- Invest in Quality Equipment:

- Use reliable tension clamps and screen printing presses for precision.

Common Challenges and Solutions

Even seasoned screen printers encounter challenges with mesh count and tension. Here are some common issues and how to address them:

- Ink Bleeding:

- Cause: Low tension or inappropriate mesh count.

- Solution: Increase tension and choose a higher mesh count.

- Loss of Fine Detail:

- Cause: Low mesh count.

- Solution: Switch to a higher mesh count and use finer ink.

- Screen Sagging:

- Cause: Poor-quality frames or overuse.

- Solution: Re-stretch the screen or upgrade to more durable frames.

How Mesh Count and Tension Work Together

The interplay between count and tension determines the overall quality of your prints. For instance:

- Low mesh count with high tension works best for printing on textured surfaces where bold designs are required.

- High mesh count with high tension is ideal for precision work on smooth substrates, such as posters or promotional materials.

Balancing these factors ensures that your prints meet professional standards, no matter the project.

Conclusion: Mastering the Science of Screen Printing

Understanding mesh count and screen tension is the foundation of professional screen printing. With the right tools and techniques, you can elevate your craft, producing prints that are sharp, vibrant, and durable. Whether you’re printing on fabric, paper, or another surface, mastering these concepts will help you deliver exceptional results every time.

Want more screen printing knowledge? Check out this article about the art, design, and separation process.

Social Media

Check us out on Instagram

Like us on Facebook

Check in on LinkedIn